Conception/construction

Do you lack the technical means to investigate a product idea or modification? We work with you to develop requirement profiles and derive comparable concepts from them. We evaluate these both technically and technologically and always keep an eye on the costs. This gives you, the customer, an initial idea of the general feasibility.

In the further process, our experts implement these ideas constructively. Particular attention is paid to the planned materials and production processes. This results in innovative construction methods with function-optimized material utilization.

Concepts

- Development of requirement profiles and application limits

- Comparison of basic solution variants

Feasibility

- Technical/technological evaluation of various solutions

Economic efficiency

- Determination of component costs

Innovation

- Innovative construction methods with functionally optimized use of materials

- Adaptation or development of optimized production processes

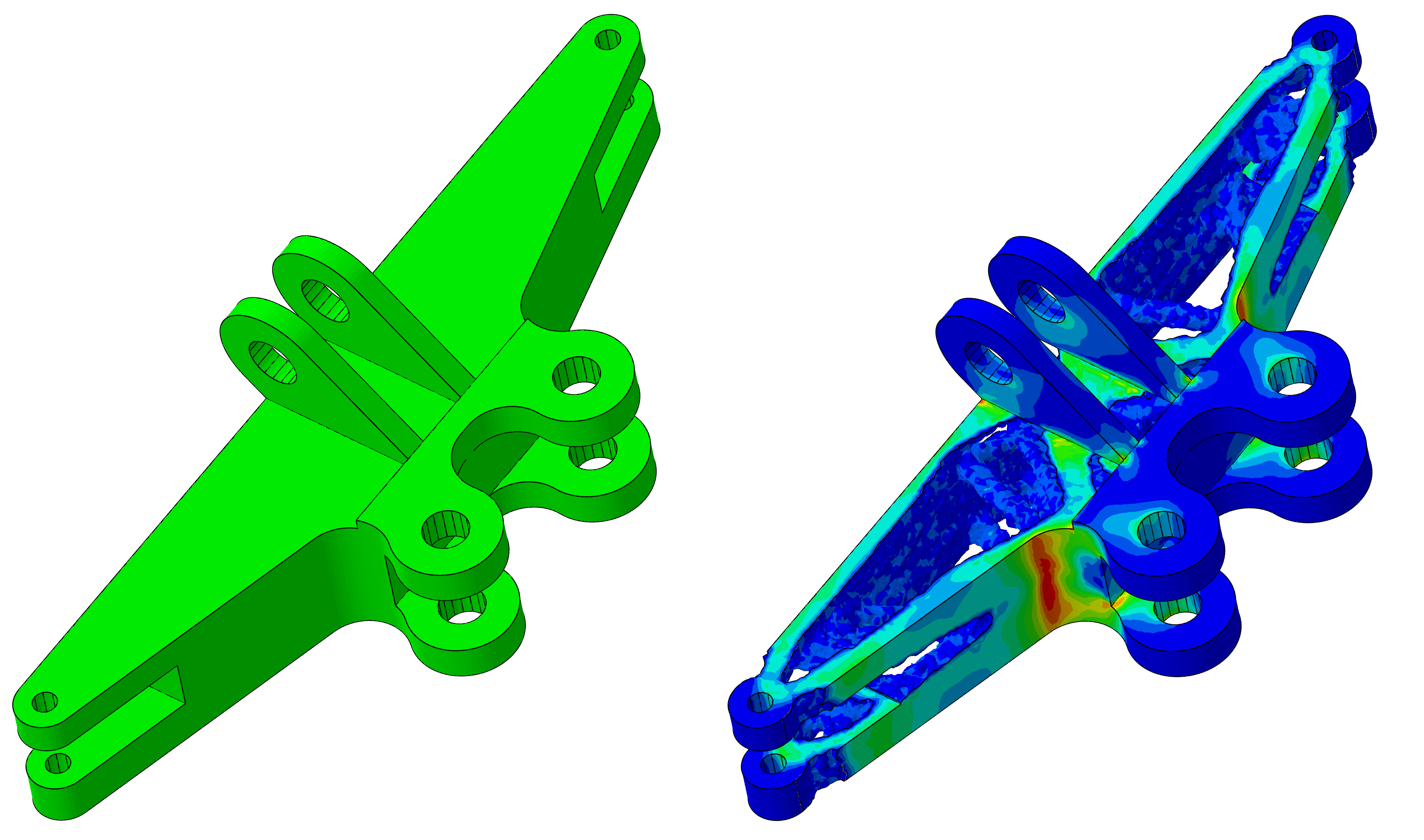

Load path analysis

“Form follows function” – If only the installation space and loads are known, load path analysis methods such as topology and topography optimization provide initial ideas for the future design. We support you with your product ideas with form and parameter studies using the Tosca® and iSight® tools.

For fiber composites, we have special routines that give priority to strength and perform a subsequent stiffness adjustment based on a load-bearing component.

- Topology and topography optimizations for load path analysis

- Parameter studies (DOE, Monte Carlo)

- Special routines for composite components

- Optimization from strength = structure is load-bearing

- Consideration of fracture mode-related failure criteria (Cuntze)

- Optimization against fatigue already possible in the earliest design phase

Prototype construction

The Realize network of partner companies offers our customers the opportunity to quickly and flexibly implement near-series prototype production of new developments in the industrially relevant manufacturing processes for thermoset composites. In addition, we also support you in finding the right manufacturer for the series production process and supervise its introduction right through to the end. Thanks to our many years of experience, we can identify quality-critical process parameters and develop strategies for industrial quality assurance.

Processes

- Near-series production in important FRP processes (RTM, VAP, prepreg)

- Product-specific adaptation/optimization of the systems

Quality

- Determination of q-critical process parameters

- Creation and implementation of industry-oriented QA strategies