virtual testing

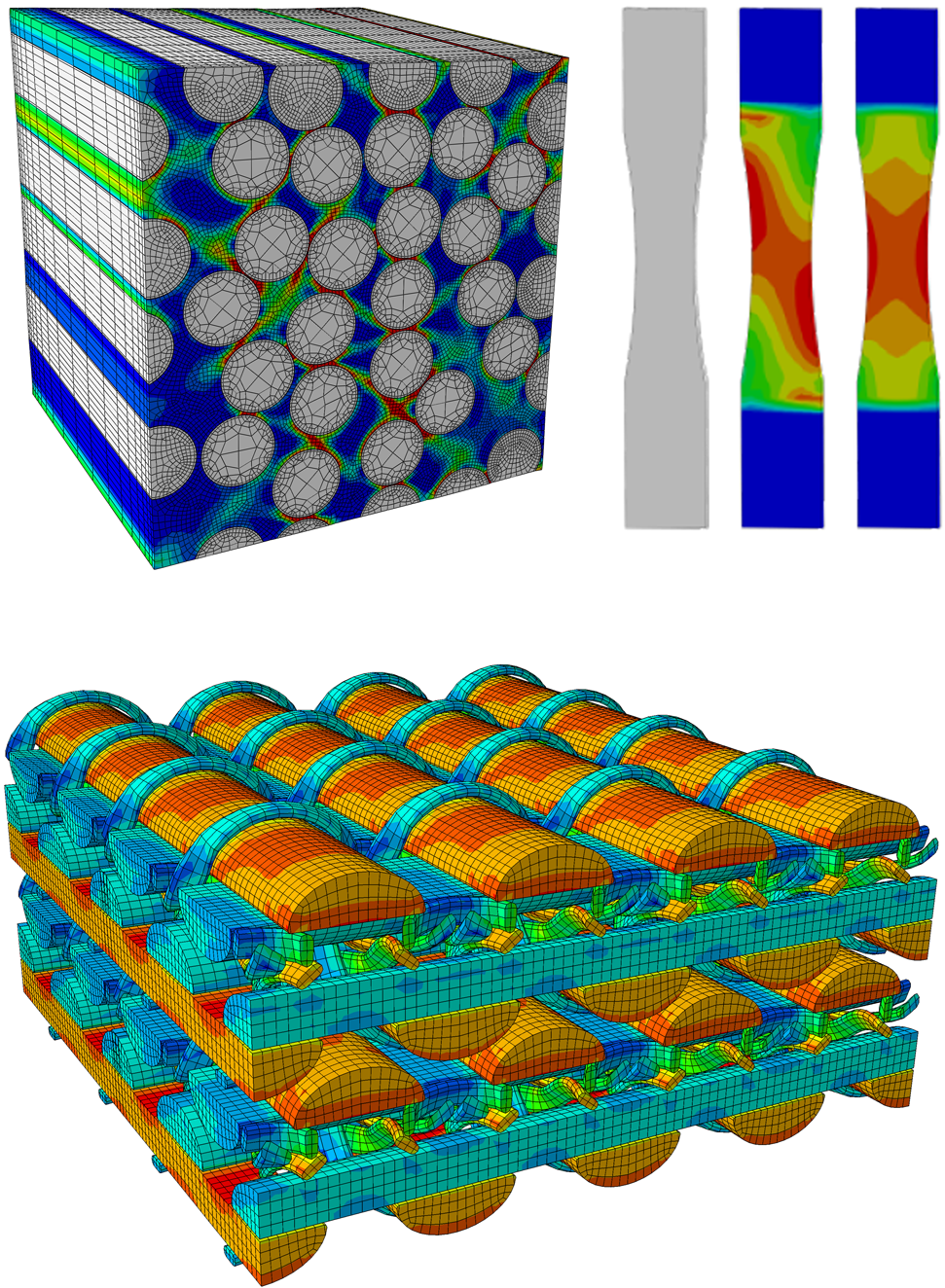

A deep understanding of the material and its behavior forms the basis for new development strength. A cross-scale methodology provides an insight into almost any depth. Where an experimental test is just a single question to nature, virtual testing can often provide more answers. The visualization of the chronological sequence of damage-relevant events allows an assessment of technologically unavoidable imperfections such as ondulation, holes or pores. The question of the influence of a modified matrix system on the expected laminate properties can therefore also be answered. The development of specific material models and new failure criteria for fabric composites, for example, creates the necessary tools for efficient design. This allows your components to be optimized early on in the development phase, resulting in better product performance while simultaneously reducing costs for product development and manufacturing.

- Cross-scale virtual testing for a deeper understanding of materials

- Calibration of material cards

- Evaluation of the influence of imperfections (ondulation, holes, pores)

- Determination of material data for composites from component properties

- Influence of a modified matrix system on the laminate properties

- Specific material models

- Development of new failure criteria for e.g. tissue composites

material models/subroutines

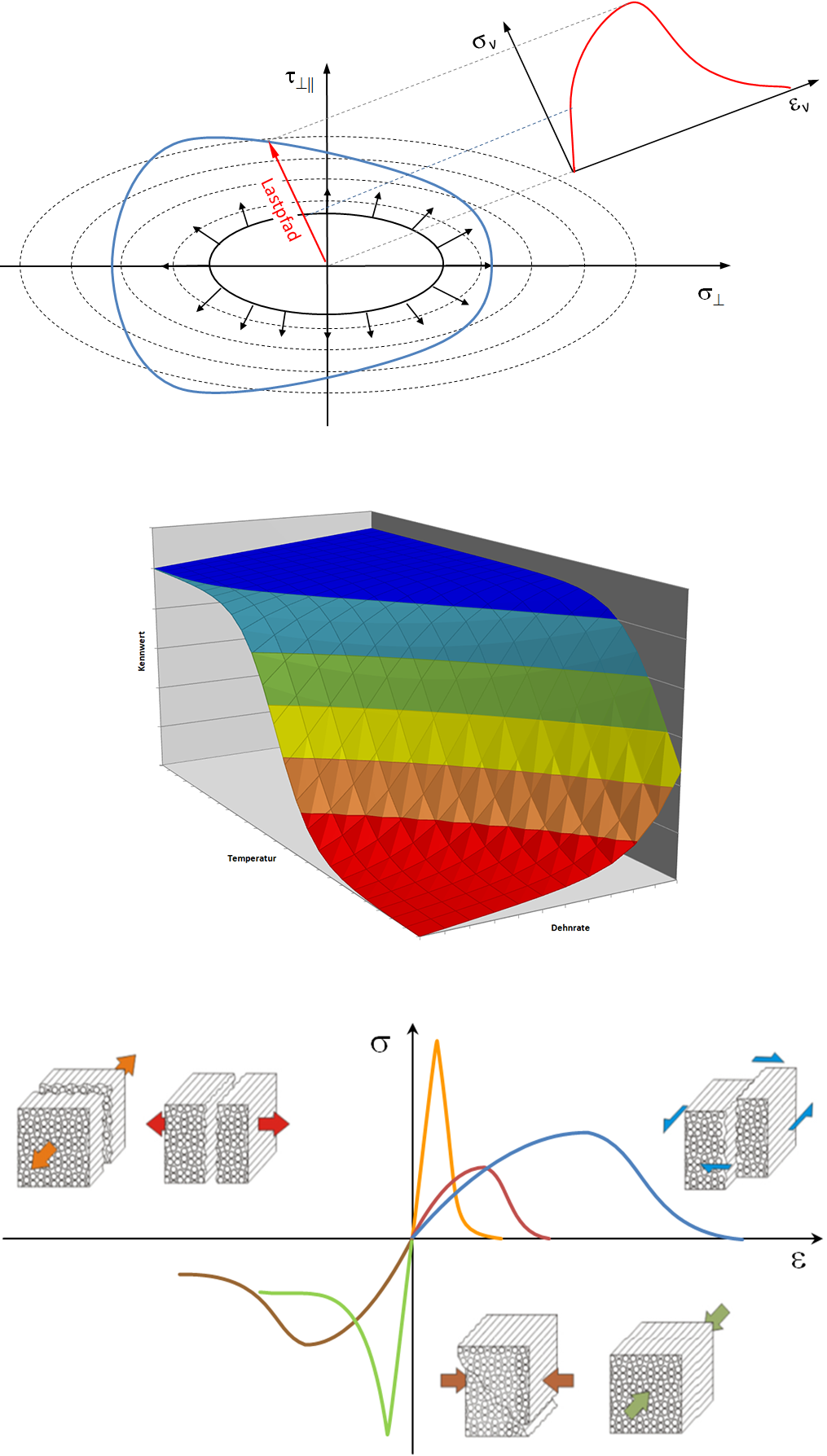

Reliable structural analysis requires powerful tools. Not only the software environment, but above all the integrated material models define the scope for the development of your components. We have a material model for fiber-reinforced plastics that clearly exceeds the possibilities of standard descriptions. The combination of orthotropic elastic/plastic behavior and realistic failure concept allows the reliable description of the deformation and strength behavior of fiber-reinforced polymers. Whether the matrix is thermoplastic or thermoset is irrelevant. Furthermore, the post-fracture behavior is also described in relation to the fracture mode. All necessary characteristic values are formulated as a function of strain rate and temperature. Whether as a black box on your premises or on our IT infrastructure – it is deployed via subroutines for Abaqus Standard and Explicit. Permanent further development and adaptation for your specific problems is possible at any time. Talk to us!

- Orthotropic elastic/plastic behavior

- Asymmetric strengths with failure mode-related failure concept (e.g. Cuntze)

- Fracture mode-related degradation

- All parameters are fully described as a function of temperature and strain rate

- Particular suitability for thermoplastic composites and continuous fiber-reinforced thermosets

- Implementation via subroutines for Simulia/Abaqus Standard and Explicit

- Extension to grid-independent damage behavior in progress