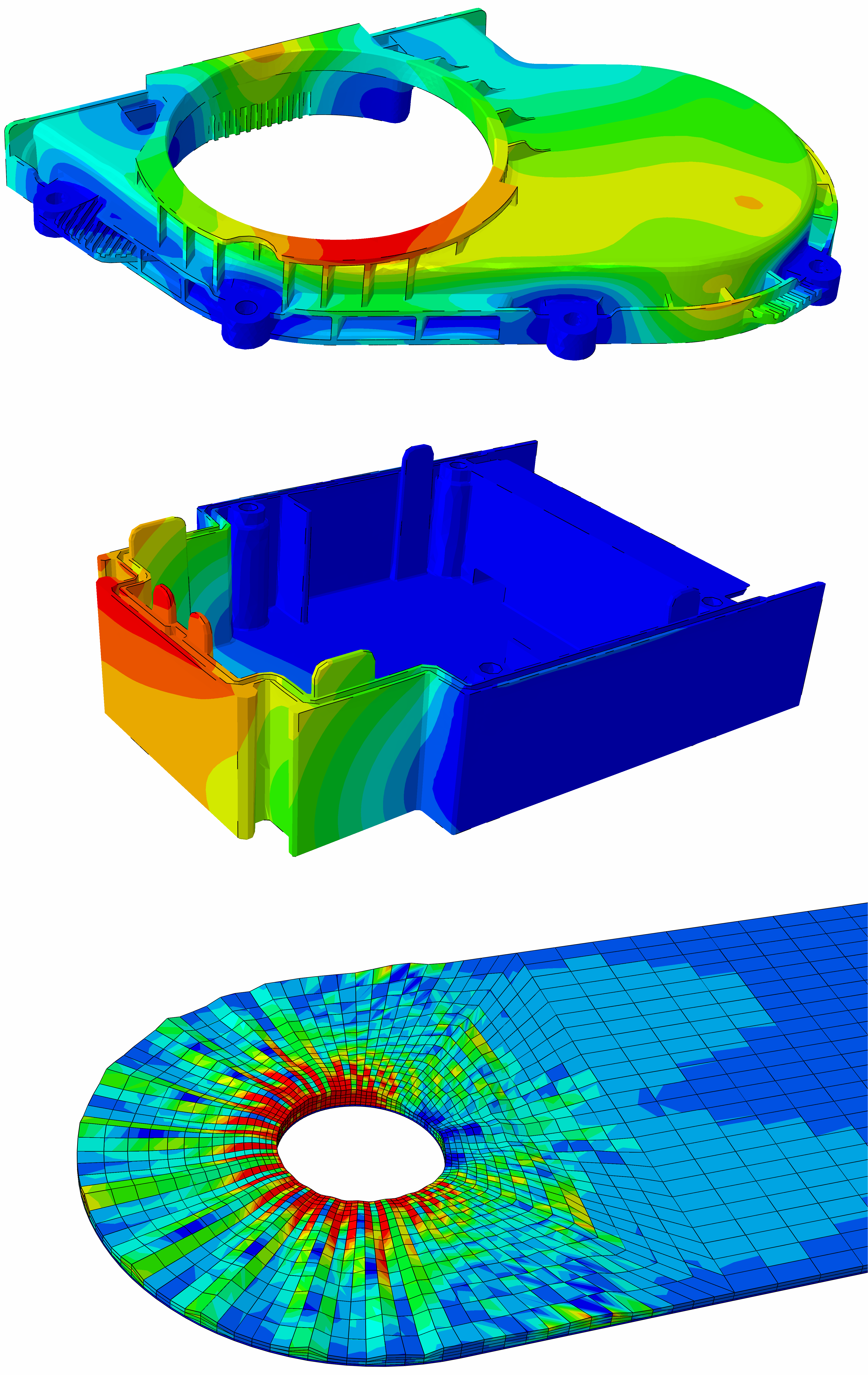

Static and quasi-static structural calculation

The majority of the structural mechanics calculations usually carried out are of a static or quasi-static nature. By neglecting mass inertia or alternatively by including appropriately scaled equivalent loads, we carry out strength verifications for a large number of components.

Whether prestressing due to screw connections or large deformations of the structure – the multitude of computational challenges require the use of a powerful simulation environment. With 20 years of professional experience in Simulia/Abaqus, Realize Engineering has a great deal of expertise in this field.

The realistic mapping of elastic/plastic material behavior, also for fiber composites, is one of our company’s core competencies.

Thermal and thermomechanical effects can also be superimposed. The design of shrinkage- and distortion-compensated components in any combination of materials paves the way for high-quality components. The mapping of the technical/technological relationships opens up the choice of sensible tolerance requirements and reduces the manufacturing costs for your component.

The simulations also form the basis for calculating the service life of the components to be developed.

- Proof of strength

- Thermomechanical and thermal analyses

- Shrinkage and warpage

- Geometrically and materially non-linear behavior

- Basis for the service life analysis

- Screw connections

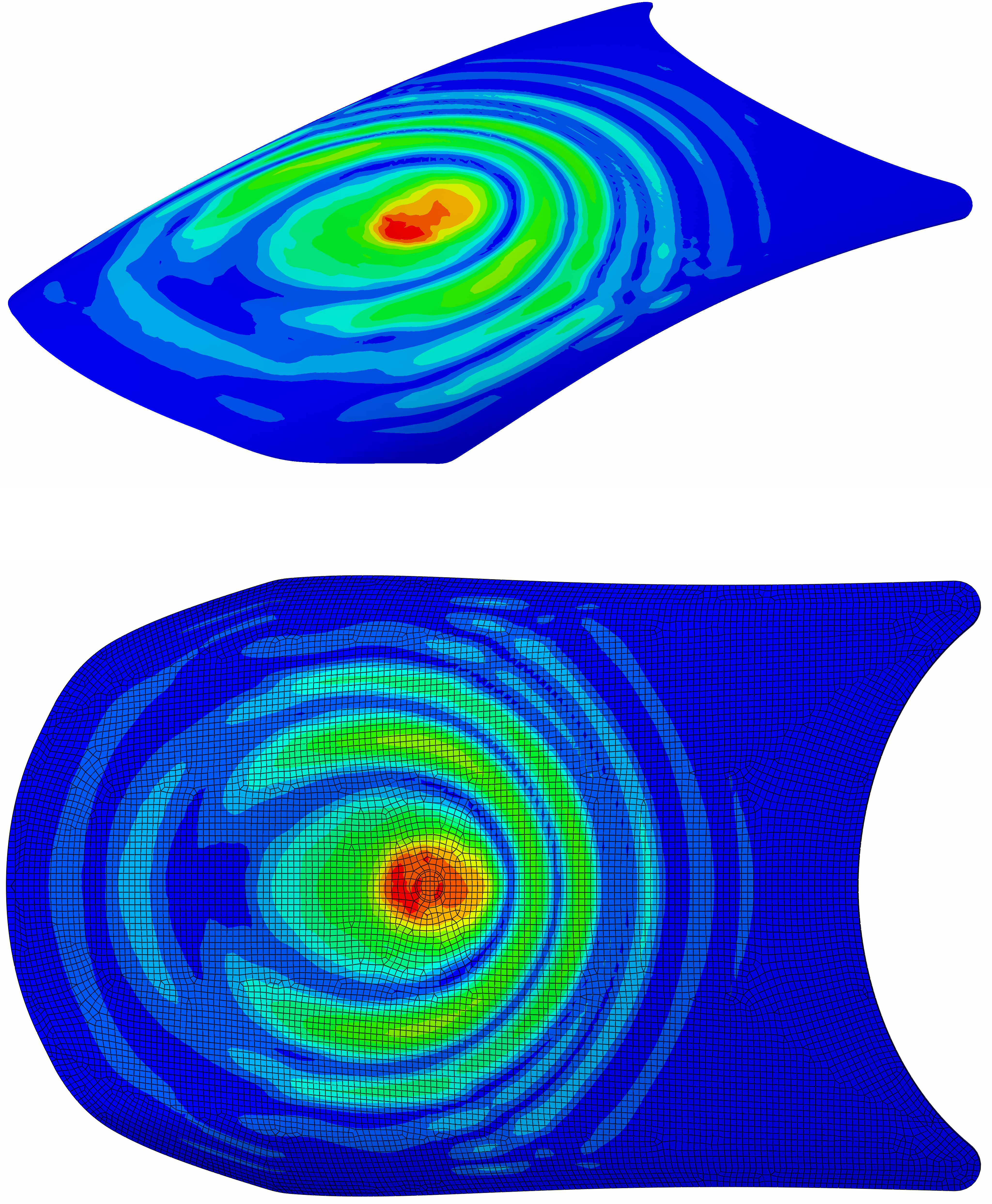

Dynamic structural simulation

Natural frequency analyses can often still be carried out within the CAD environment. If mass and inertia effects play a major role in the structural-mechanical design, then we are the right partner for you!

Mechanisms or unstable systems, such as snapping or latching processes involving contact models, can be efficiently analyzed by us.

In addition to solid structures, we also simulate the interaction of liquids and containers and dynamic excitation. Both the transient analysis of shock loads and the harmonic analysis of the steady state can be mapped realistically.

Joining processes with large deformations, e.g. for seals, are also mapped dynamically. Just ask us!

- Calculations of structural dynamics taking into account mass and inertia influences

- Natural frequency analyses of solid structures and liquids in containers (interaction of tank contents and chassis)

- Shock and vibration analyses (transient or harmonic)

- Stationary oscillation, frequency response behavior

- Resonance behavior

- Coupled multi-field problems e.g. tank swash

- Mechanism analysis (unstable systems, such as snapping or latching processes)

- Wave propagation in the overall system after impact or shock processes

- Joining simulation of sealing systems

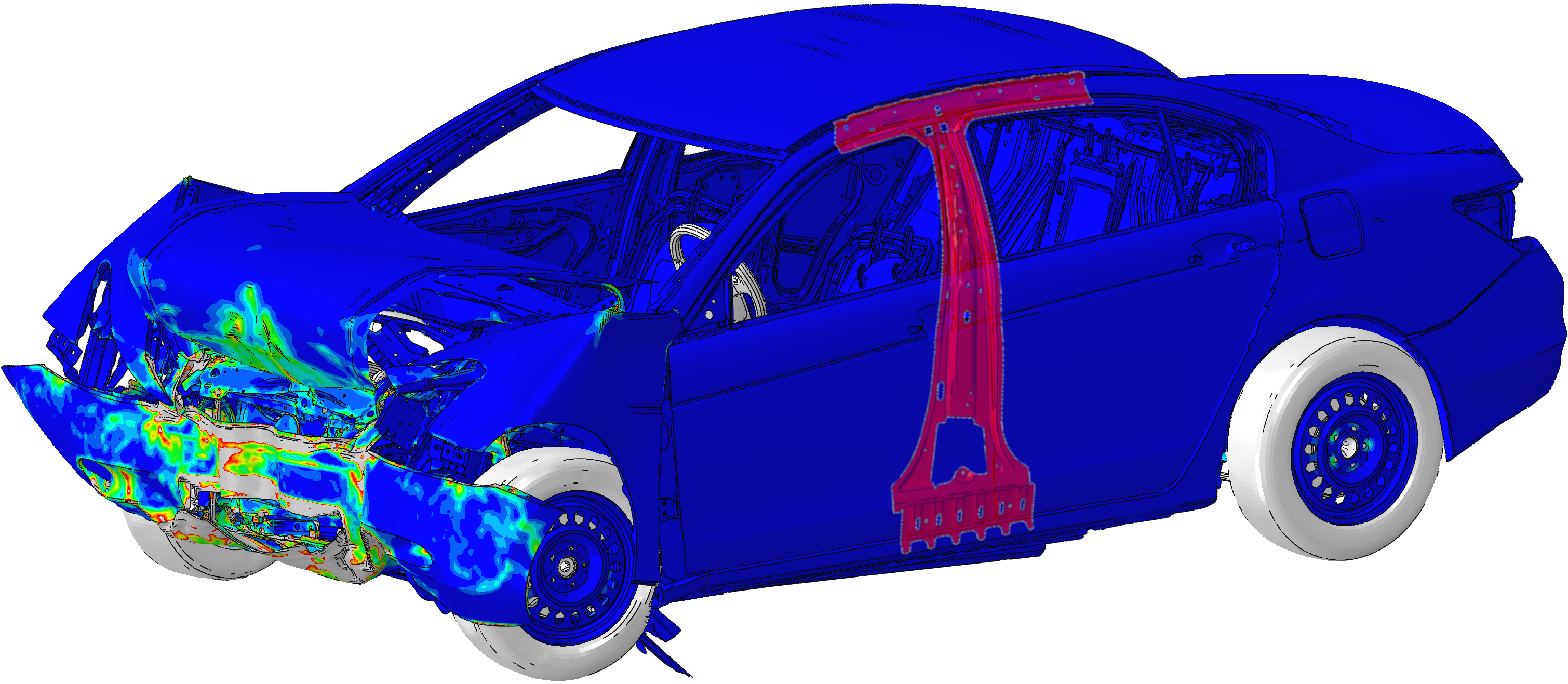

Crash/impact simulation

Crash and impact processes are a special field of dynamic analysis. We have many years of experience in short-term dynamics, both at overall vehicle and component level as well as in the simulation of e.g. high-speed tensile tests.

Crash simulations demonstrate their cost-saving potential, particularly in test preparation.

We are happy to support you!

- Progressive damage to metals, composite materials and ballistic substitutes (e.g. gelatine bird)

- Material models natively available in the FE program

- Own material models (subroutines)

- Strength verifications, design and construction method studies

- Wall, side and barrier impact and pile intrusion

- Complete vehicle models of cars/trucks available

- Analysis of the influence of lightweight structures

- Integration of new components in complete vehicle models

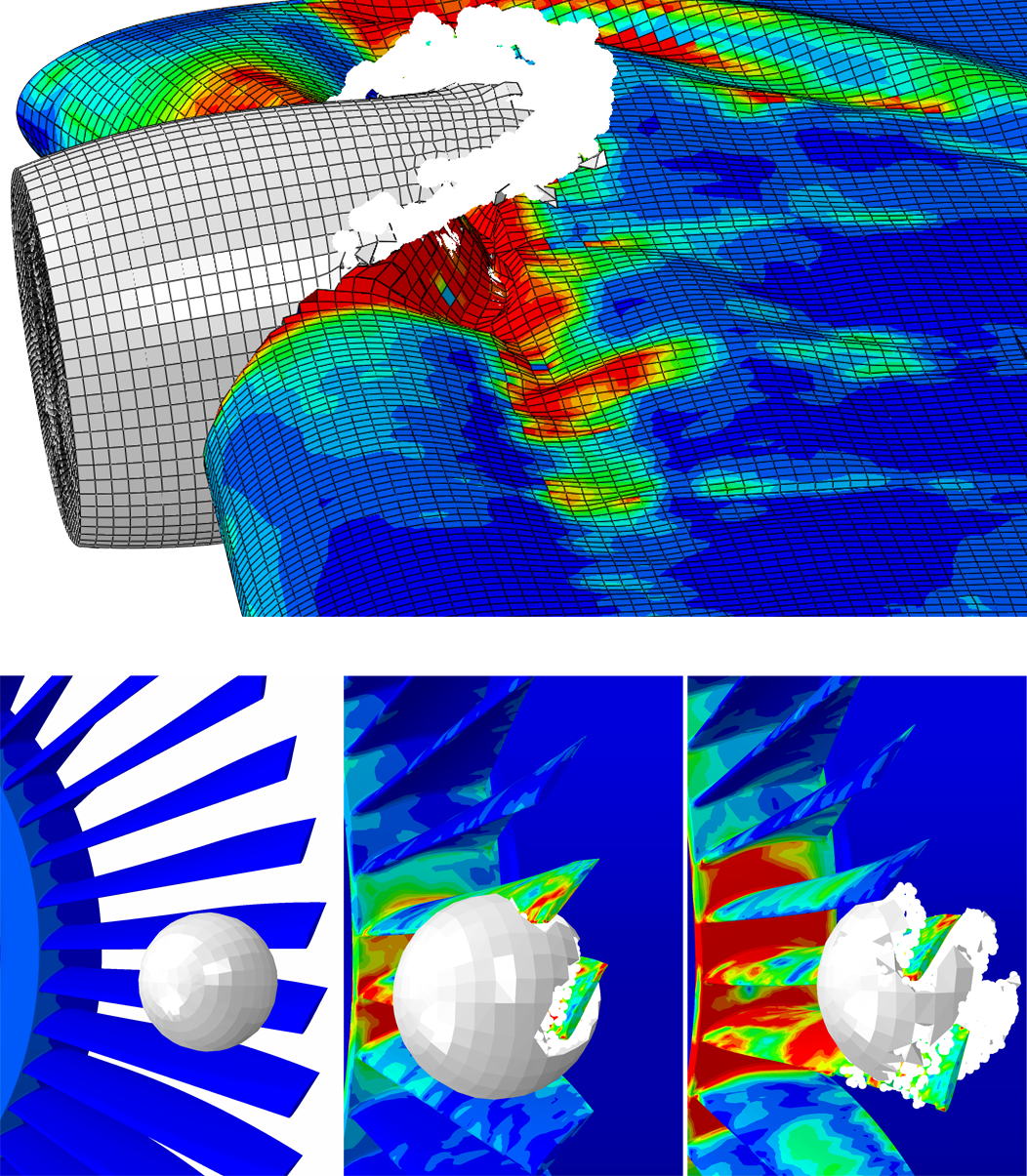

Multi-field simulation

Located between the classical fields of solid mechanics and fluid mechanics, multi-field simulation combines the advantages of both numerical descriptions. Wherever liquids interact with the wall of their transport vessel and the behavior of both partners needs to be analyzed, the focus is on multiphysical simulation. Whether bird or ice impact on aircraft structures or impact loads on filled tank structures – our many years of experience in the development of fiber composites up to series production readiness will also help to solve your specific problem. Just ask us!

- Hail and bird strike

- Combined Euler/Lagrange/SPH modeling

- Impact loads on filled tank structures

- Identification of the cavitation tendency

- Determining the influence of lightweight construction

- Optimization of the layer structure in parametric design studies

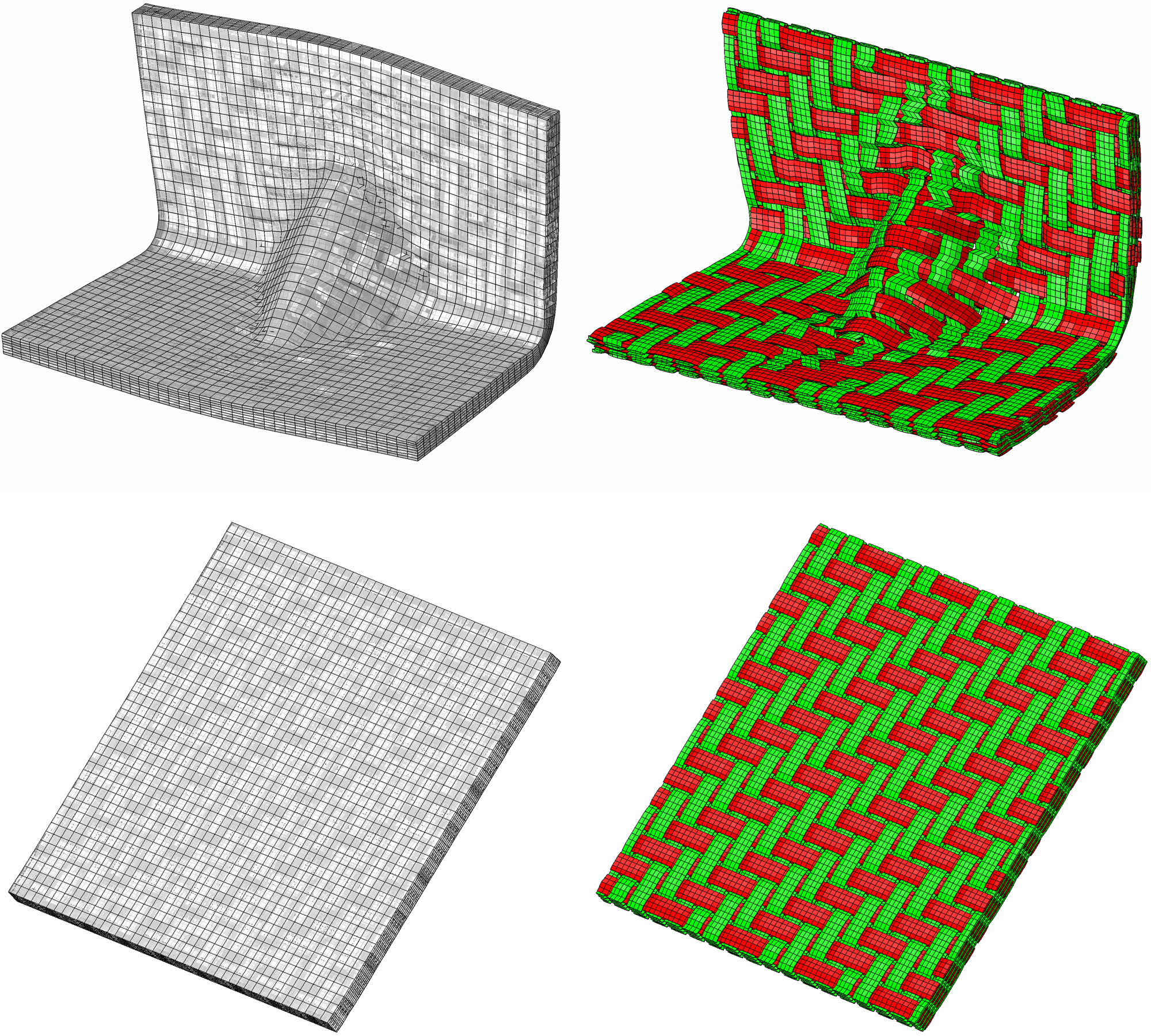

Process Simulation

A product cannot be better than the process behind its creation!

A deep understanding of technical/technological interrelationships leads to a new development strength, because knowledge of the relevant influencing factors makes it possible to relax cost-driving tolerance requirements and get to know your product better.

- Forming simulation (organic sheet, deep drawing, hole forming, clinching, punch riveting process)

- Winding simulation (loss of thread pre-tension during overwinding)

- Process-relevant imperfections

- Determination of influencing factors in variant studies

- Residual stress analysis during the curing process (spring-back, sping-in)

- Derivation of distortion-compensated tool surfaces

- Prediction of the surface quality (Class A) during hot pressing or classic curing and identification of the causes of waviness